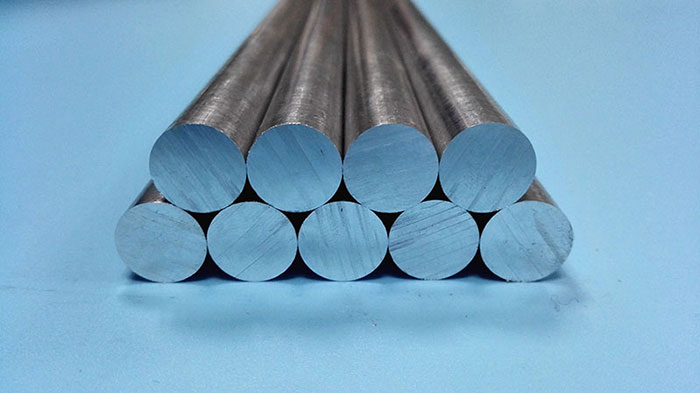

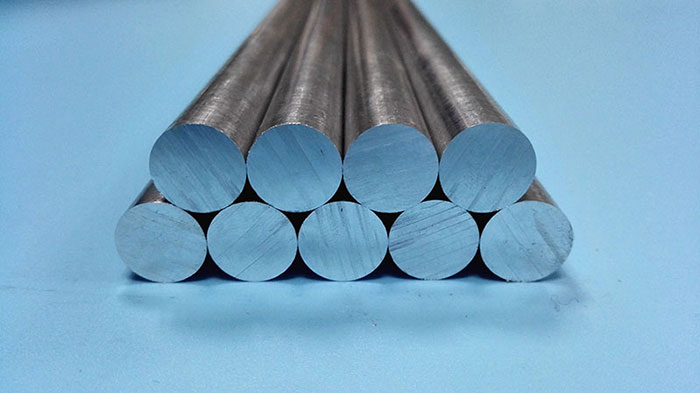

There are 300331035049,6n0160056005a, 606160826063,7n017003702170297129 alloy commonly used in the automobile industry. The 3-Series aluminum alloy is used for extruding pipes, while the 7-series aluminum alloy is mostly used for producing automobile bumpers, etc. The 6-series aluminum alloy is the most commonly used and the largest production aluminum alloy for extruding, which is mostly used for the production of building profiles.

At present, extruded aluminum profiles are widely used in the automobile industry. Their properties should meet the design requirements. The technological parameters of each process in production should be strictly controlled. First, qualified components and dense ingots should be expended to ensure that the profiles have excellent static and dynamic strength and good ductility and toughness after heat treatment. Therefore, extruded profiles are used for manufacturing No doubt, the performances of the auto parts made by our company are better than those of the casting products, which is of great help to improve the safety of the auto parts.

The current

extruded aluminum alloy for automobile can not meet these requirements. At the same time, it has received the impact and challenge of new and alternative modern materials such as fiber reinforced plastics and high-strength low alloy steel. The aluminum industry is actively responding to this severe situation, developing a batch of new aluminum alloy to meet the material requirements of the next generation of high-performance lightweight vehicles. On the other hand, the performance of the existing aluminum alloy is carried out Transformation is also one of the effective ways to solve this challenge. Henan Chalco is one of the most effective enterprises in the research and development of automotive extrusion aluminum alloy. We were founded in the 1950s. Recently, we have formulated a plan to develop four types of

extruded aluminum alloy for automobile with eight different properties, so as to meet the needs of the automotive industry, with tensile strength greater than 330n / mm2 and high damage resistance Injury tolerance performance.

AS29 alloy, with tensile strength of 500N / mm2 and strong corrosion resistance

As86 alloy. It has very high tensile strength at room temperature, which is higher than any aluminum alloy now

As03, as81, as47 alloy, tensile strength < = 305n / mm2, but has strong impact resistance, which is developed for manufacturing impact resistant parts

Aluminum alloy with good extrudability is used to extrude complex porous automobile profiles. Its tensile strength should be greater than 330n / mm2, and it has strong damage tolerance.