Extruded aluminum materials used in automobile manufacturing have profiles, pipes and bars. The sections and pipes are used more, the amount of rod used is very small, and it is used for cutting and cutting some small parts. With the rapid development of China's auto industry and the rapid development of vehicle lightweight, the average annual growth rate of automobile extrusion aluminum consumption is estimated to reach 15% or more in the next 10 years.

The extruded aluminum 90% is made of 6 series alloy, with less 3 series, 5 series and 7 series alloy. In the form of extruded profiles and pipes, it is used in the manufacture of automotive parts.

International standard alloy elements commonly used in automotive aluminum alloys %

|

Alloy |

Si |

Cu |

Mn |

Mg |

Zn |

Others |

|

3003 |

- |

0.05~ 0.2 |

1.0~1.5 |

- |

- |

- |

|

3103 |

- |

- |

0.9~1.5 |

- |

- |

- |

|

5049 |

- |

- |

0.5~1.1 |

1.6~2.5 |

- |

- |

|

6N01 |

- |

- |

- |

- |

- |

- |

|

6005 |

0.6~ 0.9 |

- |

- |

0.4~0.6 |

- |

- |

|

6005A |

0.5~ 0.9 |

- |

- |

0.4~0.7 |

- |

0.12~0.50(Mn+Cr) |

|

6061 |

0.4~ 0.9 |

0.15~ 0.40 |

- |

0.6~1.2 |

- |

0.04~0.35Cr |

|

6063 |

0.2~ 0.6 |

- |

- |

0.45~0.9 |

- |

- |

|

6082 |

0.7~ 1.3 |

- |

0.4~1.0 |

0.6~1.2 |

- |

- |

|

7N01 |

- |

- |

- |

1~2 |

4~5 |

- |

|

7003 |

- |

- |

- |

0.5~1.0 |

5.0~6.5 |

0.05~0.25Zr |

|

7021 |

- |

- |

- |

1.2~1.8 |

5.0~6.0 |

0.08~0.18Zr |

|

7029 |

- |

- |

- |

0.5~0.9 |

4.2~5.2 |

|

|

7129 |

- |

- |

- |

0.5~0.9 |

4.2~5.0 |

|

|

7075 |

0.40 |

1.2~2.0 |

0.30 |

2.1~2.9 |

5.1~6.1 |

Ti 0.2 |

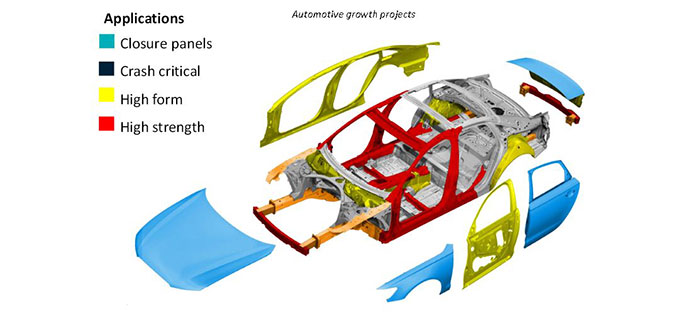

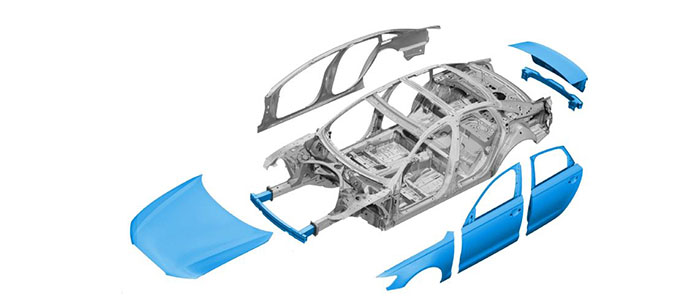

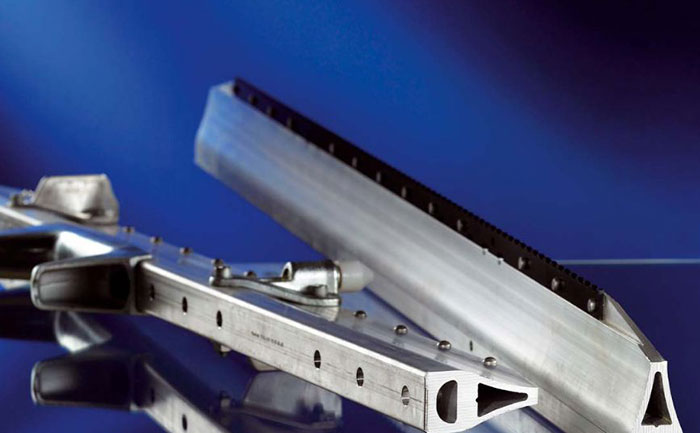

In the car body frame, at present, the main body is the steel single hull structure, and the body occupies 30% of the vehicle quality. Therefore, the manufacture of extrusion aluminum is of great significance for vehicle lightweight, energy saving and emission reduction and the construction of low carbon transportation industry. Aluminum Alloy extrusion performance is good, can be hollow thin-wall profile production section of the complex, making the bumper body structure and use them, body quality can reduce 30%--40%, and has the same impact strength and steel structure, when the vehicle collision accidents, can absorb the impact effectively, protect the safety of people.

Most of the aluminum alloys in the car body frame are extruded with 6 series and 7 series. In order to strengthen the impact strength, the sections of the profiles are mostly“口”、“日”、“目”、“田”. The strength of 7 series alloy alloy is higher than that of 6 series alloy.

Mechanical properties of aluminum alloy profile of body frame

|

Alloy Temper |

Tension strength Rm/N∙mm¯² |

YieldStrength Rp0.2/N∙mm¯² |

ElongationA5/% |

General corrosion resistance |

Corrosion resistance of stress corrosion cracking |

Weldability |

Compresability |

|

6063 T5 |

185 |

145 |

12 |

Good |

Good |

Good |

Good |

|

6N01 T5 |

275 |

245 |

12 |

Good |

Good |

ok |

Good |

|

6061 T6 |

310 |

275 |

12 |

ok |

Good |

ok |

Good |

|

7003 T5 |

360 |

325 |

18 |

ok |

ok |

Good |

Nomal |

|

7N01 |

380 |

315 |

17 |

ok |

ok |

Good |

Not good |

Mechanical Properties and Impact Test Data of Automobile Aluminum Alloy Profiles with Hollow and Complex Cross Section

|

Profile type |

Tension strengthRm/N∙mm¯² |

Yield strength Rp0.2/N∙mm¯² |

Elongation A5/% |

Section size |

Mass ratio* |

Buffer strength ratio |

Buffer deformation ratio* |

|

口 |

365 |

325 |

15 |

60×60 |

1.00 |

1.0 |

1.0 |

|

日 |

350 |

315 |

14 |

60×60 |

1.18 |

1.34 |

0.341 |

|

目 |

360 |

320 |

14 |

60×60 |

1.37 |

1.61 |

0.610 |

|

田 |

340 |

305 |

11 |

60×60 |

1.41 |

1.48 |

0.230 |